SUTHERLAND SHIRE

HYDROBLASTING

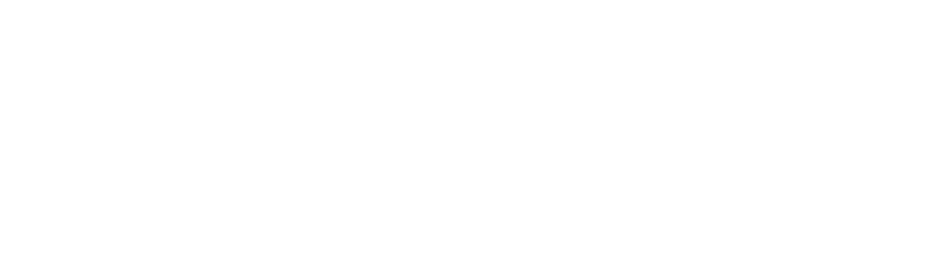

The new non-destructive way to strip clean metals

What is Hydroblasting?

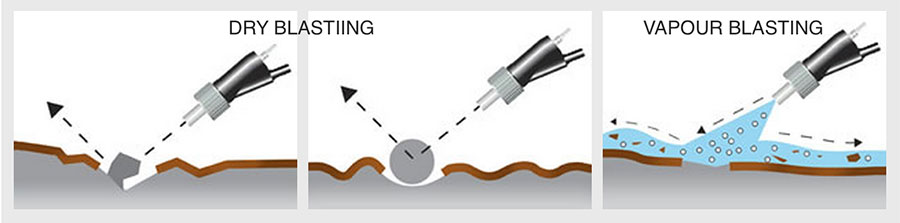

Hydroblasting uses a pressured stream of water to flow over the parts being processed. Hydroblasting has a lot of advantages over conventional sandblasting or bead blasting as it is a cleaning and polishing process in one. We use a fine high-quality glass bead as our primary media.

The glass bead media is forced at pressure on to the workpiece by a special slurry pump combined with compressed air. All the work is carried out and contained in an enclosed cabinet and the machine has a closed loop water system.

The hydroblasting process will gently clean and polish the surface to a satin polished type finish. Hydroblasting is completely non-destructive unlike dry sand blasting which relies on firing a dry particle at high velocity, relying on impact of angular media to achieve a result.

Advantages of Hydroblasting

- Non-destructive cleaning

- No dimensional changes or warping

- Environmentally friendly

- Dust-free process

- Removes industrial coatings without damage

- Promotes longer media life meaning less contamination

- Produces a ‘softer’ finish

- Avoids media impregnation on soft material

- Cleans non-ferrous metals for restoring and maintaining the part

Wheel Restoration

We offer wheel restoration services that will bring your rims back to life. Whether it is chipped, curb damaged, gutter scuffed or a vintage rim, we specialise in repair and restoration to all alloy wheels. Our state-of-the-art technology is designed to accommodate for any sized rim.

Hydroblasting Process

When bringing or sending your work to Zeid hydroblasting, please note:

All components must be free from paint, heavy grease and dirt deposits prior to hydroblasting. In many cases customers have their own facilities to paint strip, de-grease and pre clean their own parts saving themselves money. We can offer to degrease and paint strip your parts prior to hydroblasting but this is outsourced and will add to costs. Price on application.

Hydroblasting only removes grime, oxidation and tarnishing in a non-destructive way whilst also gently peening and polishing the surface, closing the pores of the material in most cases leaving a better than original finish resistant to further tarnishing, fingerprints and dirt.

We will always rinse the parts that have just been hydroblasted in water and dry by using an air supply to blow dry.

Although we use a flash rust inhibitor in our mixture, in the case of steel parts we may also apply a protection spray. This will force moisture off the part and further reduce the risk of rusting.

This is only a temporary measure and we suggest you get any non-porous metals parts primed soon afterwards. We can offer this service, just email us your request to info@zeidgroup.com.au and we will prepare a quote for you.

Engine cases, engine parts must be stripped of all bearings, gaskets, valves, fittings and parts for best results, we can still clean the parts with these items fitted but it is done at the customer’s risk.

Frequently Asked Questions

We will wash processed parts after hydroblasting and whilst every effort is made to ensure no glass bead media remains on or in the item, we advise when you receive your parts you re-wash and check parts carefully before assembly as any glass beads left behind could cause engine or machine damage. This is very important and it is the customer’s responsibility to wash and blow the part clean before fitment. We cannot emphasise this enough.

As long as your parts can sensibly fit within our cabinet and be comfortably blasted we can undertake your work, the approximate dimensions of our door is 850mm high x 800mm deep and the cabinet is 915mm wide, we need to be able to comfortably move the blasting nozzle around the parts to complete the work.

Blasting will be charged at $90.00 per hour. Min charge is 30 minutes ($45.00).

What can be hydroblasted?

See our gallery below for more examples.

Can hydroblasting deburr my parts?

Mass production and CNC machining leave tiny burrs on these components which are not removed by the factory before being sold.

Hydroblasting makes the new part better than new, smooth and burr-free.

What about flash rusting?

We also apply a rust preventative to studs and other steel parts that may rust. It is recommended that steel items like screws, throttle linkages, bolts etc. be plated soon after hydroblasting.

Can you blast complete engines?

Must I strip everything down e.g. carbies?

Complete banks of carbies must be stripped and separated as well. You will have to strip them anyway to plate all the non-alloy parts so they do not rust.